BSM-520W

5-Axis Wet Milling Machine

Versatile Milling from Ceramics to Metals

The BSM 520W is a state-of-the-art 5-axis wet milling machine engineered for high precision, reliability, and intelligent processing. Designed to handle demanding metal blank and bar milling with ease, it features a solid gantry structure made of high-strength cast iron and a thermal symmetry design for unmatched stability. Equipped with a 16-tool magazine, a premium spindle, an intuitive CAM nesting system, and a smart touch screen, the BSM 520W ensures efficient, precise, and intelligent milling performance.

Key Features & Advantages

1. Unmatched Precision

✔ Digital servo system with high-resolution control

✔ Installation accuracy: ±0.01mm

✔ Milling precision: ±0.005mm

2. Exceptional Reliability

✔ Gantry structure & thermal expansion symmetric design ensure excellent stability

✔ B-axis rotation range (-30° to +30°) supports custom milling needs

3. High-Efficiency Milling

✔ Fast milling speeds for various restorations:

- Full contour posterior crown (TC4 14mm) ≈ 20 min

- Coping (TC4 14mm) ≈ 15 min

- 3-unit full contour bridge (TC4 14mm) ≈ 40 min

- 3-unit coping bridge (TC4 14mm) ≈ 30 min

- Frame (TC4) ≈ 2 hours

- Customized abutment (TC4) ≈ 30 min

- Implant bar ≈ 3.5 hours

All data based on BSM 520W milling of TC4 material.

4. Intelligent Processing

✔ Power-off protection prevents data loss

✔ User-friendly 13.3” LCD touch screen for seamless operation

5. Advanced Tool Management

✔ 16-tool automatic tool changer for uninterrupted milling

✔ Tool life monitoring optimizes tool usage cycles

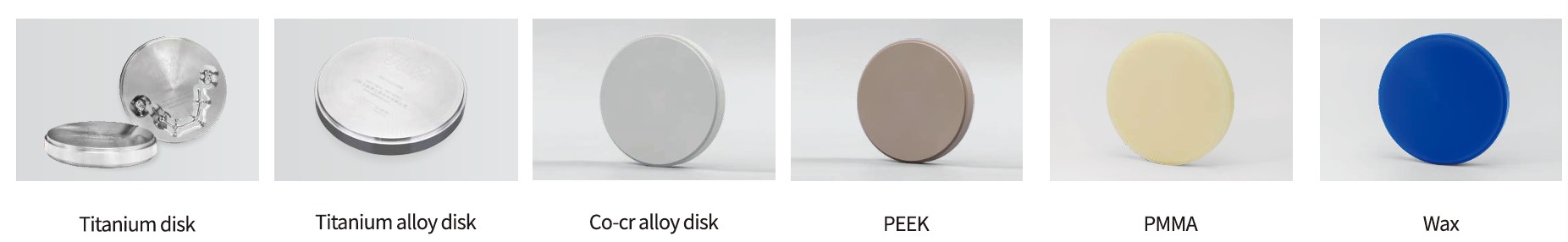

Restoration Materials

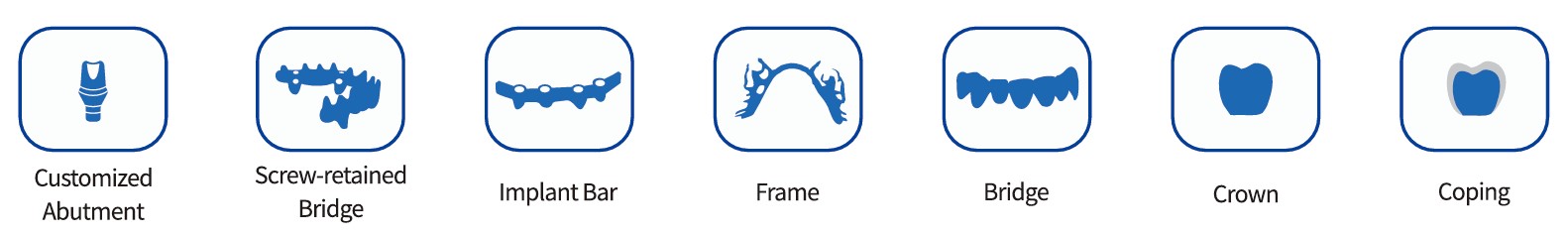

Restoration Types

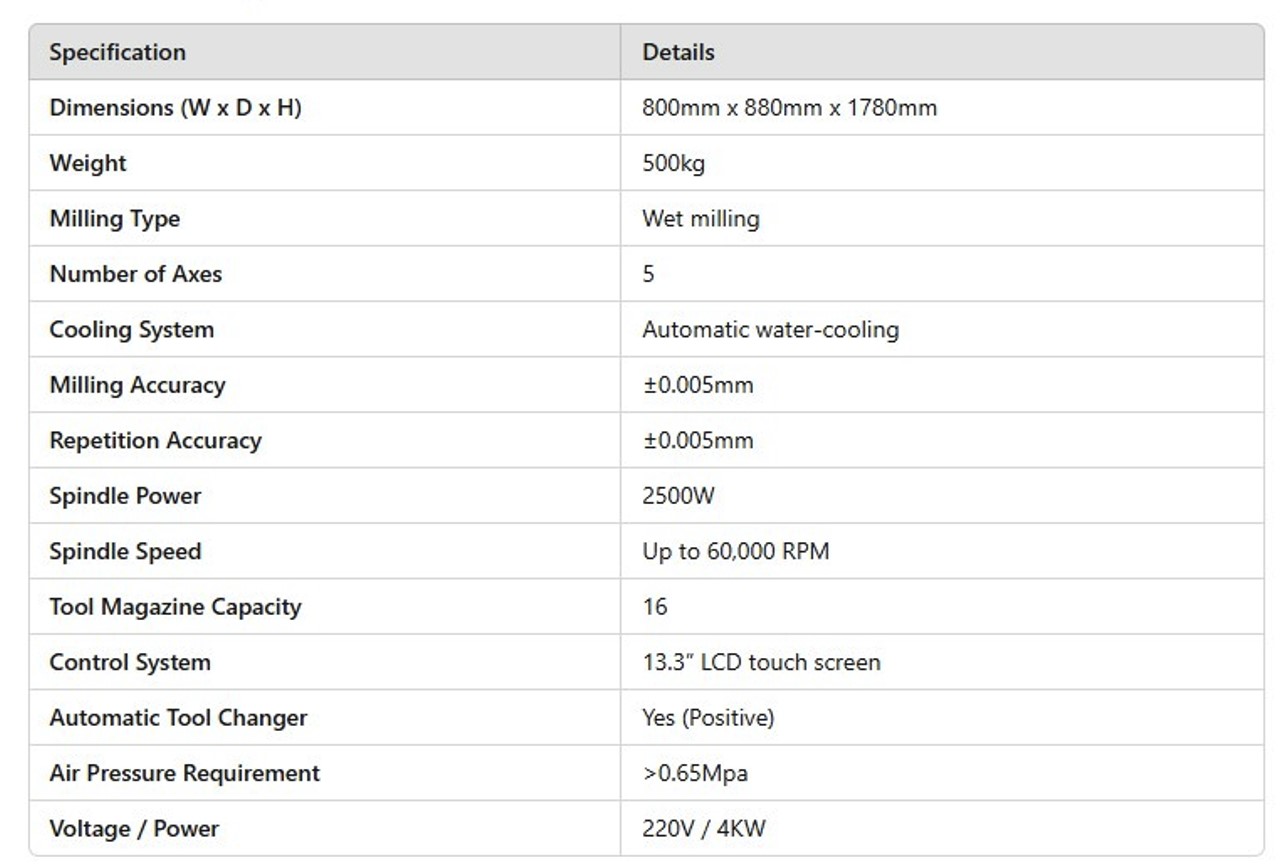

Specifications

Request a Quote

If you are interested in acquiring this equipment, we would be delighted to assist you. Please feel free to fill out our contact form with your details and specific requirements, or give us a call at your convenience. Our team is ready to provide you with all the information you need and guide you through the purchasing process to ensure you make an informed decision.