UP3D – P53

5-Axis Intelligent

Dental Milling Machine

A Smarter, More Hassle-Free Partner

For Dental Laboratory

The P53 Five-Axis Intelligent Dental Milling Machine is a state-of-the-art dental dry milling device that seamlessly integrates an intelligent control system with a unified structure. By injecting intelligent capabilities into dental prosthesis production, it aims to significantly support the scalable manufacturing of dental laboratories.

Dust-Proof Slides Extend Operational Lifespan

Streamlined Material Switching With Custom BK-1 Clamps

The innovative BK-1 clamp design enables rapid disc and block material changes in seconds, optimizing production efficiency.

Precision 90° Milling For Realistic Restorationss

The five-axis synchronous technology enables 90° vertical aesthetic dry milling, complemented by a 0.3mm micro-carving cutter. This intelligent solution precisely integrates efficient, realistic restoration, ensuring consistently high-quality dental prosthetics that deliver natural-looking, life-like outcomes for patients.

Smart Remote Control

MillMind software provides remote control, smart milling reminders, and tool life monitoring capabilities enable effective production oversight.

Precision And Stability With One-Click Calibration

One-click smart calibration simplifies operations, automatically optimizing the machine’s accuracy and stability. This feature reduces milling errors, minimizes material waste, and enhances overall efficiency, empowering users to consistently produce high-precision dental prosthetics with exceptional quality and reliability.

C-Clamp Design

Smart LED Display Strip

CNC Multi-Machine Control

Resume Milling At Breakpoint

Tool Life Monitoring

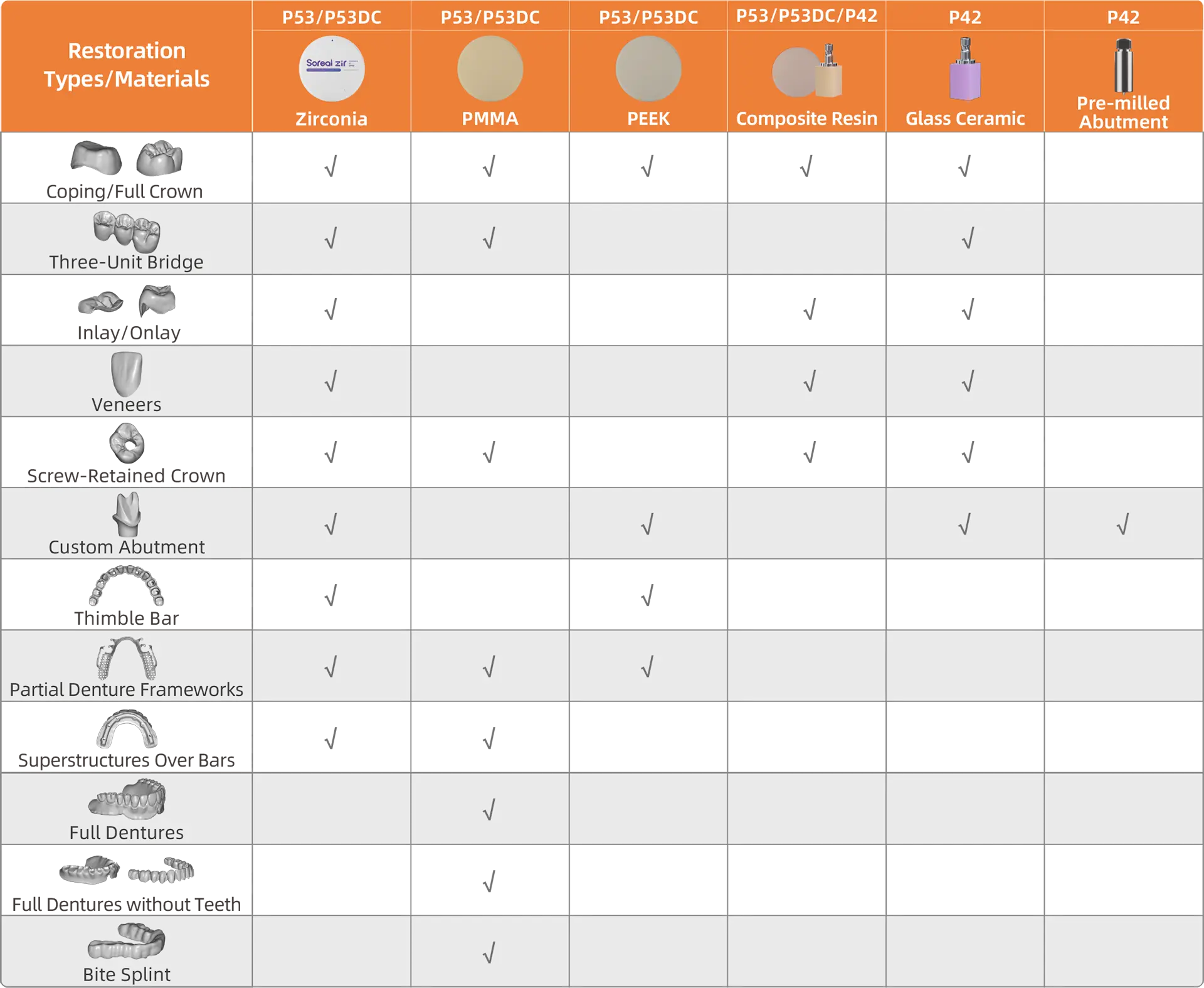

Restoration Types/Materials

Specifications

| Model | P53 |

| Dimension | 443.5*718*628.5mm |

| Weight | 87kg |

| Input Voltage | AC 100-240V |

| Maximum Power | 1.1KW |

| Spindle Power | 0.35KW (max) |

| Number of Axes | Five-axis simultaneous |

| Milling Range | X/Y/Z: 167/200/90mm, A:±30° B:±360° |

| Milling Type | Dry milling |

| Max Spindle Speed | 40,000rpm |

| Max Feed Rate | 3000mm/min |

| Tool Quantity | 11 |

| Tool Change Method | Automatic (air pressure > 0.5MPa) |

| Spindle Cooling | Compressed air (air pressure 0.15~0.20MPa) |

| Materials | Zirconia, wax, PMMA, PEEK, cobalt-chromium soft metal, composites |

| Milling Time |

Coping: Zirconia 10 minutes, Wax 4.5 minutes

Full crown: Zirconia 13 minutes, Wax 5.5 minutes |

| Material Size | Discs: height 10-30mm, diameter 98mm Blocks up to 40*20*20mm |

| Spindle Clamping Diameter | Φ4.0mm |

| CAM Support | UPCAM, Millbox |

| Data Transmission | Network interface |

Request a Quote

If you are interested in acquiring this equipment, we would be delighted to assist you. Please feel free to fill out our contact form with your details and specific requirements, or give us a call at your convenience. Our team is ready to provide you with all the information you need and guide you through the purchasing process to ensure you make an informed decision.