UP3D – P42

4-Axis Wet Milling Machine

Superior Quality, Immediate Fit

The P42 dental wet milling machine can process 3 ceramic blocks or 1 titanium rod simultaneously, with deep software-hardware integration. It seamlessly integrates with the SOREAL Immediate Restoration System, simplifying the digital workflow from scanning and design to milling. Features like pure water milling, undercut removal, remote control, and automatic calibration ensure precision and quality. This versatile, user-friendly solution significantly boosts the efficiency of restorative creations.

Pure water grinding and milling eliminates additives, reducing costs and material wear. This eco-friendly approach simplifies operations by avoiding complex waste disposal, ushering in a safer, more economical era of dental restorations.

The A-axis’ ±20° oscillation and UPCAM technology enable targeted undercut removal, avoiding complex manual adjustments. This precise machining process guarantees a perfect fit for dental restorations of up3d dental milling machine P42.

Smart Remote Control, Enhanced Productivity And Efficiency

MillMind software provides remote control, smart milling reminders, and tool life monitoring capabilities enable effective production oversight.

Smart Remote Control, Enhanced Productivity and Efficiency

Integrates negative ion technology to significantly reduce static from resin debris, enhancing cleaning efficiency. This creates a tidy work environment and fosters a comfortable machining experience.

Automatic Tool Changing

Resume Milling At Breakpoint

Dental Milling Tool Life Monitoring

Dust-Proof Slides

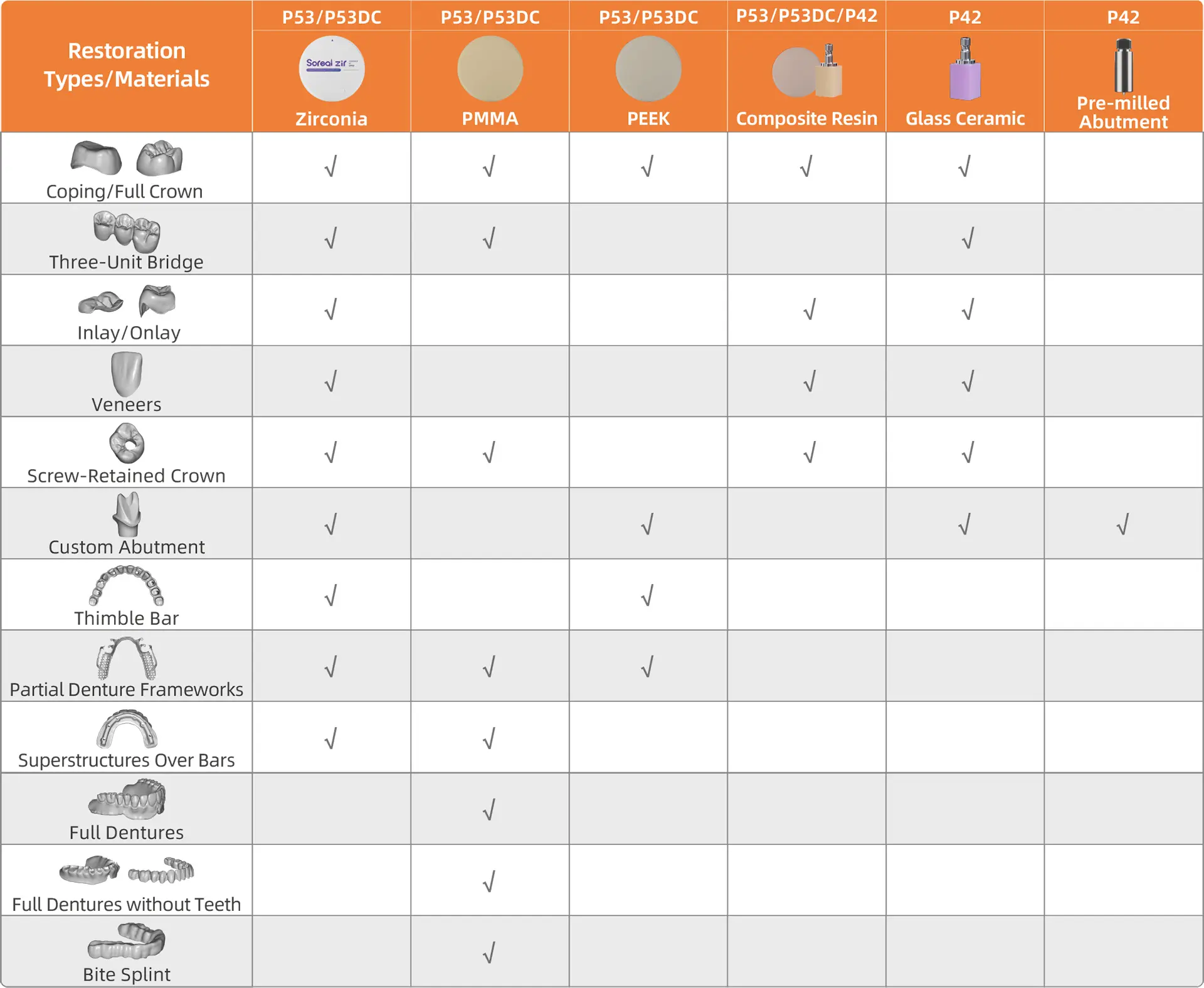

Restoration Types/Materials

Specifications

| Model | P53DC |

| Dimension | 875*720*630mm |

| Weight | 130kg |

| Input Voltage | AC 100-240V |

| Maximum Power | 1.1KW |

| Spindle Power | 0.35KW (max) |

| Number of Axes | Five-axis simultaneous |

| Milling Range | X/Y/Z: 167/200/90mm, A:±30° B:±360° |

| Milling Type | Dry milling |

| Max Spindle Speed | 40,000rpm |

| Max Feed Rate | 3000mm/min |

| Tool Quantity | 11 |

| Disc Library Quantity | 12 |

| Tool Change Method | Automatic (air pressure > 0.35MPa) |

| Spindle Cooling | Compressed air (air pressure 0.15~0.20MPa) |

| Materials | Zirconia, wax, PMMA, PEEK, cobalt-chromium soft metal, composites |

| Milling Time | Coping: Zirconia 10 minutes, Wax 4.5 minutes Full crown: Zirconia 13 minutes, Wax 5.5 minutes |

| Material Size | Discs: height 10-30mm, diameter 98mm Blocks up to 40*20*20mm |

| Spindle Clamping Diameter | Φ4.0mm |

| CAM Support | UPCAM, Millbox |

| Data Transmission | Network interface |

Request a Quote

If you are interested in acquiring this equipment, we would be delighted to assist you. Please feel free to fill out our contact form with your details and specific requirements, or give us a call at your convenience. Our team is ready to provide you with all the information you need and guide you through the purchasing process to ensure you make an informed decision.