UP3D – P55D

Air Compressor-free

Dental Milling Machine

UP3D – P55D

P55D is a new high-end dry milling machine from UP3D, designed with precision servo control and all-weather stable production technology for 24-hour efficient continuous milling. Equipped with a high-speed electric spindle from Germany and a plug-and-play design without the need for an air source, it allows for intelligent remote control. Compatible with a variety of materials, its integrated dust-proof design and structural optimization reduce maintenance and enhance efficiency. With a decade of technical accumulation and innovation, P55D significantly boosts productivity, offering end users a completely upgraded experience.

Precision Servo Control Round-the-Clock Stable Production

High-Quality Spindle German Engineering, Stronger and Air-free

Precision Servo Control Round-the-Clock Stable Production

Smart Remote Control Mill Manage at Your Fingertip

01

Integrated Dustproof Design Extended Service Life

P55D features an integrated, fully sealed silicone dustproof design, effectively isolating dust, reducing equipment damage and maintenance needs, thereby significantly extending its service life.

02

Structural Optimization Upgrade Reduced Maintenance Costs

P55D features an integrated, fully sealed silicone dustproof design, effectively isolating dust, reducing equipment damage and maintenance needs, thereby significantly extending its service life.

03

Bigger Milling Chamber Optimized Work Efficiency

A larger milling chamber provides operators with more space and flexibility, simplifying the process of material installation and removal, effectively improving work efficiency.

Technical Specifications

General

Fields of Application

Dry machining

Materials

Zirconia,wax,PMMA,PEEK,composite resin,soft milling CoCr sintering metal

Material Specifications

Discs: height 10-30mm, diameter 98.5mm Blocks up to 40x20x20mm (Max)

Indications

Base System

Construction

Machine bed made of solid cast aluminum body

Number of Axes

5-axis

Housing

Steel, white high-gloss lacquer finish, main front housing: injection-molded

Linear Axes (X/Y/Z)

Precision ball screw drive; Travel: 104x60x100mm

Rotary Axes (A/B)

A-axis: 360°; B-axis: ±33°

Control Unit

5-axis precision full servo drive system

Lighting

LED lighting inside the working chamber, with additional status indication

Power

1.0KW

SPINDLE

General

Speed

Up to 60,000 rpm

Diameter Φ4

Max. 0.8KW

AUTOMATION

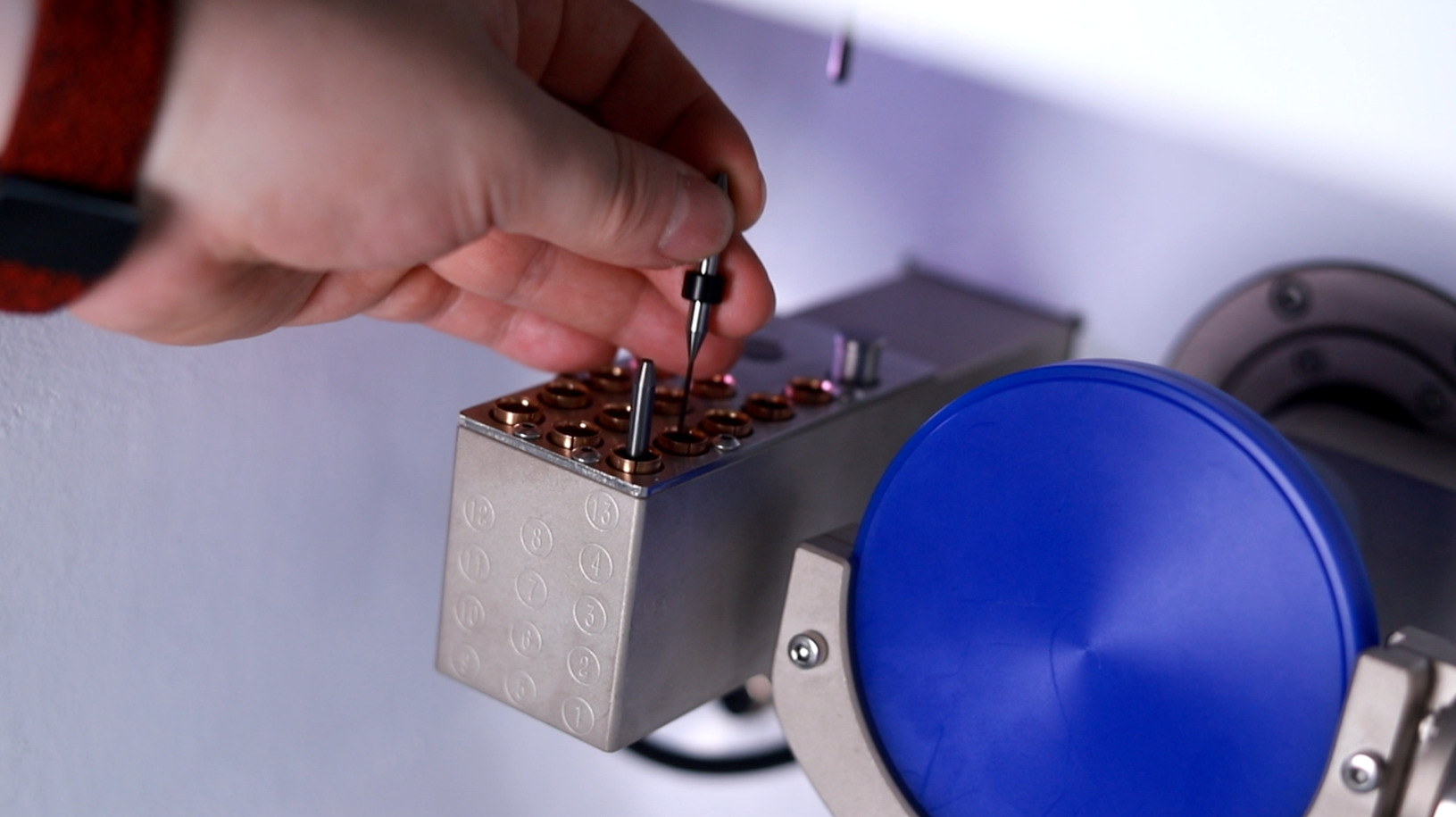

Tool Change

CONNECTION REQUIREMENTS

Voltage

Filter level: M; Flow rate: 2500L/min

Data

Wi-fi, USB, Ethernet port

ENVIRONMENTAL CONDITIONS

Operating Temperature

Between 10℃ and 35℃

Air Moisture

Below 80% (relative), non-condensing

DIMENSIONS & WEIGHTS

Dimentions

442x560x704mm

Weight

106KG

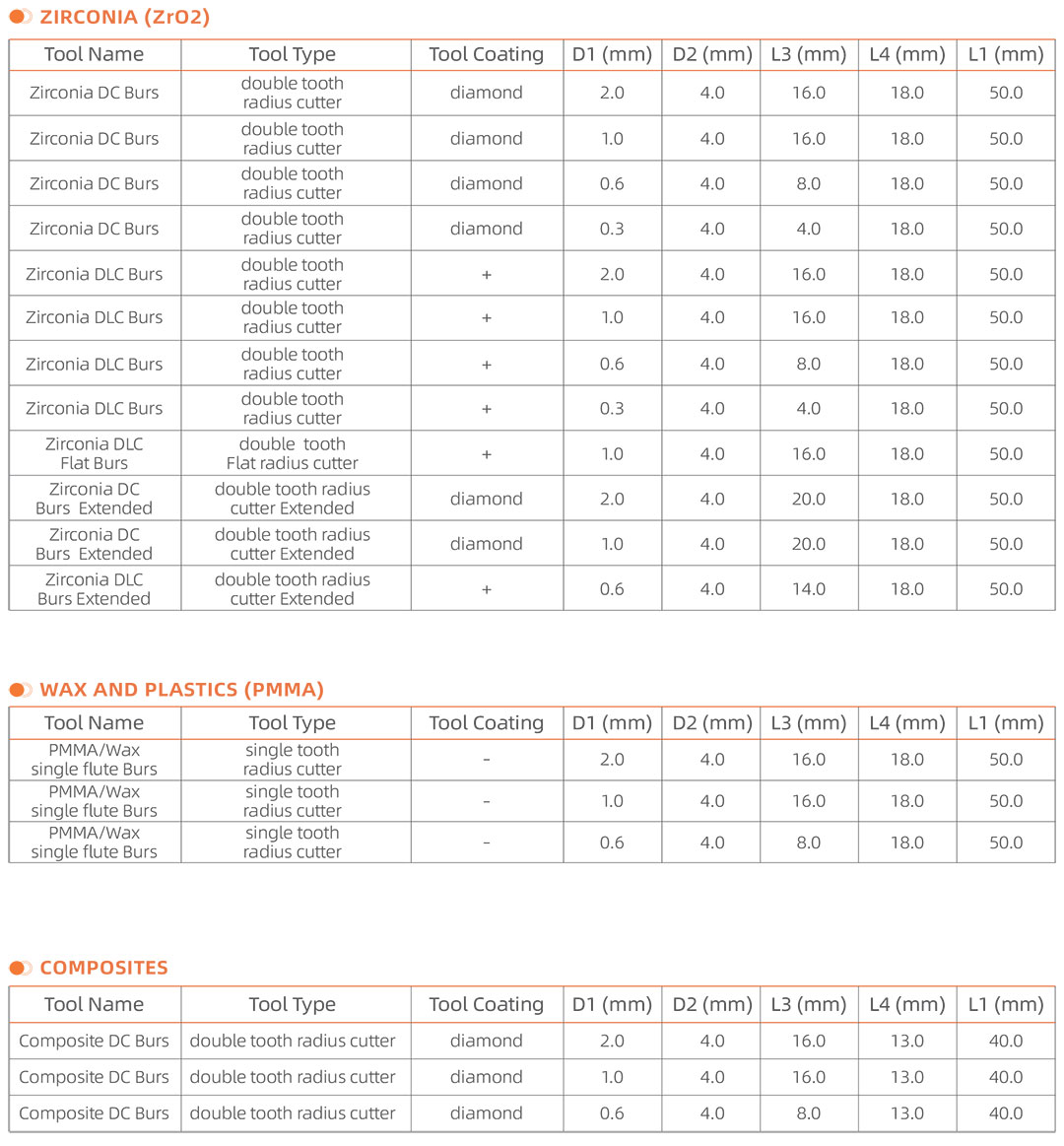

Applicable Materials

Restoration Types / Materials

Request a Quote

If you are interested in acquiring this equipment, we would be delighted to assist you. Please feel free to fill out our contact form with your details and specific requirements, or give us a call at your convenience. Our team is ready to provide you with all the information you need and guide you through the purchasing process to ensure you make an informed decision.