DEPRAG W5 Pro

5-Axis All-in-One Dental Milling Machine

W5 Pro: One Machine, Infinite Possibilities

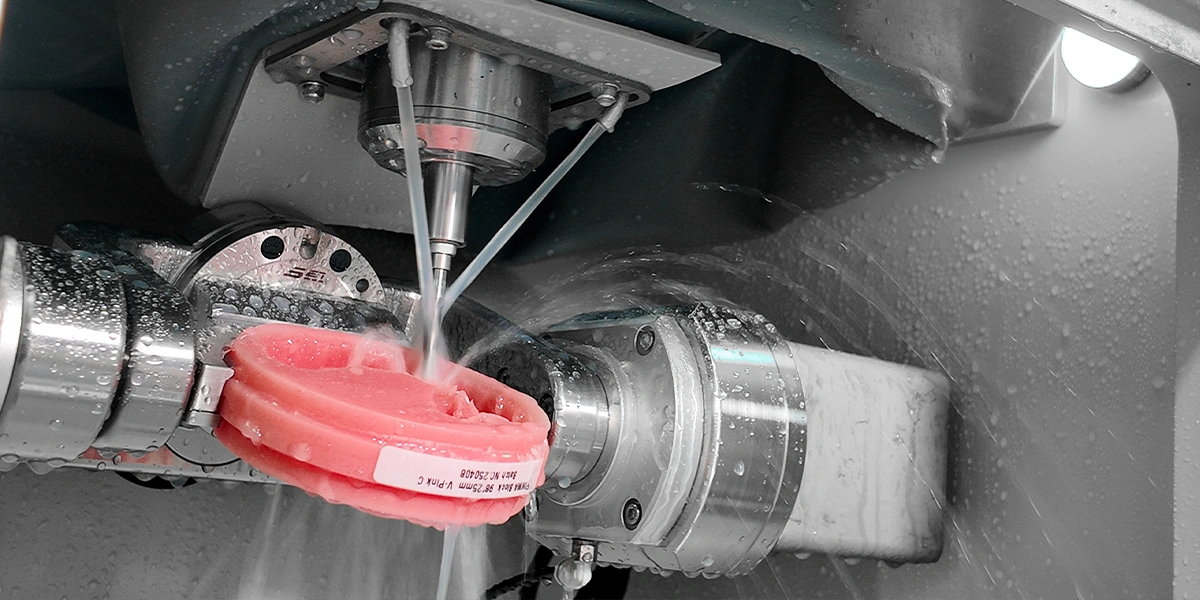

Unlock the next level of digital dentistry with the W5 Pro, our flagship all-in-one dental milling solution engineered for labs that demand precision, power, and productivity. Designed for wet and dry milling, this robust system supports a vast range of materials and indications—making it the ultimate centerpiece for any growing dental lab.

Power Meets Precision

With a 2.5kW high-torque spindle (398Ncm), the W5 Pro delivers uncompromising performance, especially for demanding materials like CoCr and Titanium. Whether you’re milling zirconia, glass ceramics, PMMA, PEEK, or wax, this machine guarantees powerful, smooth, and accurate restorations every time.

Complete Versatility

From simple crowns to complex implant bars, the W5 Pro handles it all:

-

Discs: 4-position holder

-

Pre-milled Blanks: 8-position auto-loader

-

Blocks: 8-position block holder

-

Thread milling, vertical milling (90°), and reverse clamping support expand your production capabilities.

Automation That Works for You

Experience a 30% efficiency boost with advanced features:

-

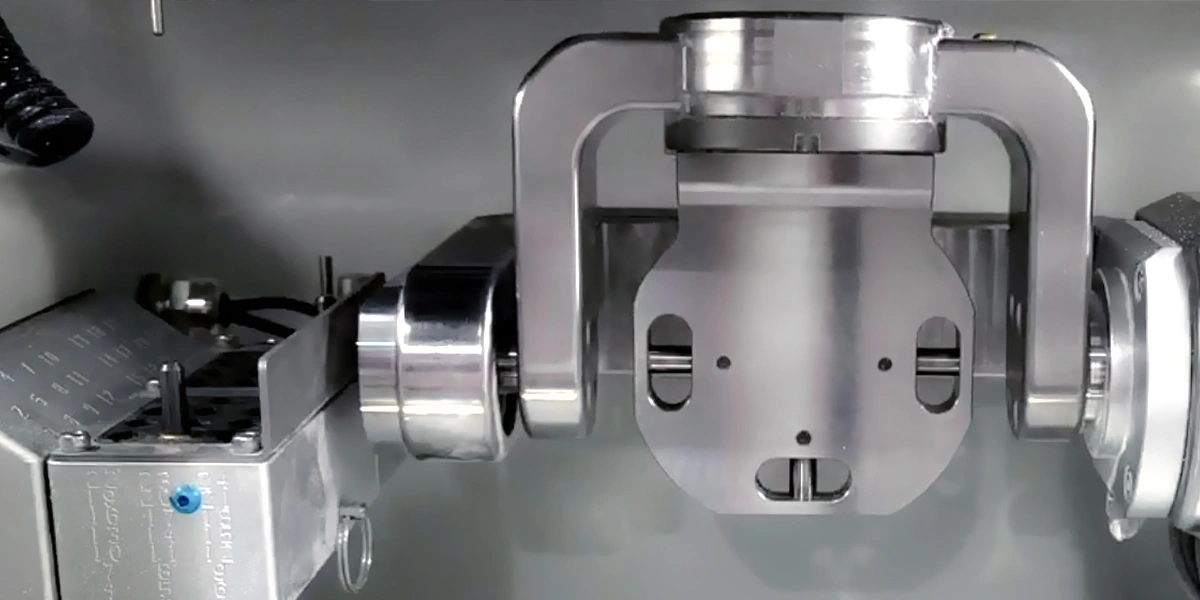

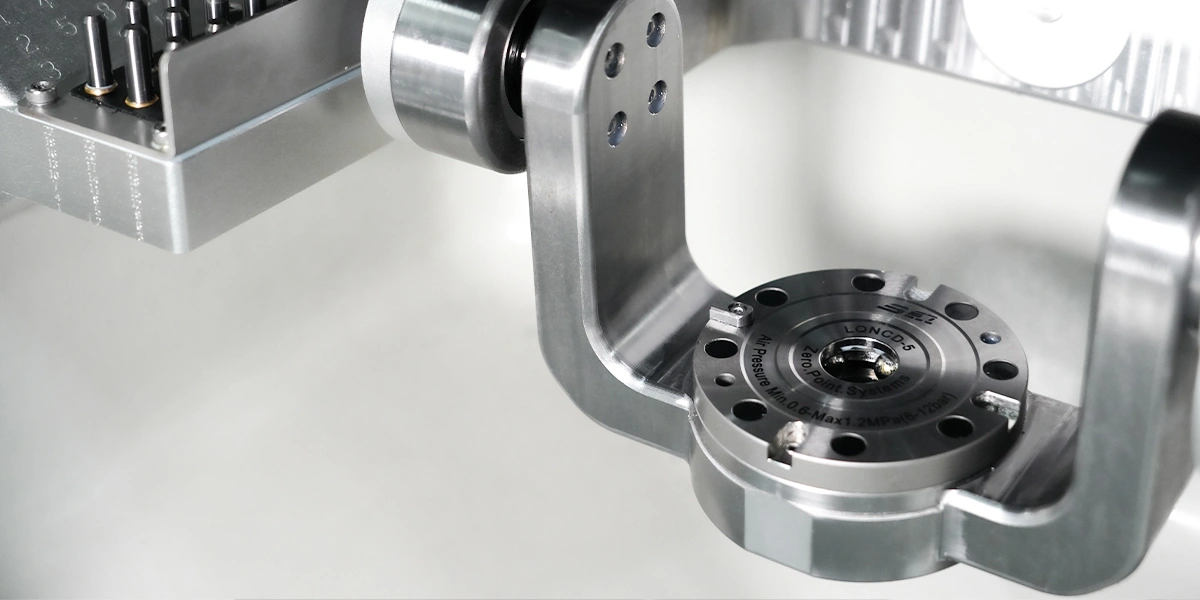

Auto-calibration: Cuts setup time from 40 minutes to under 10

-

Zero-point quick change: Swap fixtures in just 1–2 seconds

-

Smart Tool Management: Automatic tool changing and tool life monitoring

-

Fully automatic cleaning system: Dual wet/dry 360° rotating nozzles

Engineered for Stability and Longevity

The W5 Pro is built to last:

-

Cast iron frame with nickel-plated anti-corrosion protection

-

Auto-Drainage Air Filter to minimize maintenance

-

Schneider Circuit Protection and comprehensive logging ensure safe, reliable operation

-

Floor-mounted, integrated design for maximum stability

User-Friendly by Design

-

23.8” Touchscreen (Windows 10 OS)

-

Built-in HD camera for live monitoring and recording

-

Remote access via PC or mobile

-

Easy-to-use software and intuitive interface for smooth daily operation

Compatible Materials

-

Metals: Titanium, CoCr

-

Ceramics: Glass ceramic, zirconia

-

Polymers: PMMA, PEEK, Wax

-

Composites and Others: Model resin, splint resin, and more

Supported Indications

Crowns, bridges, abutments, veneers, inlays/onlays, implant bars, screw-retained bridges, secondary crowns, telescopic crowns, protrusion splints, surgical guides, model plates, model dies, and more.

W5 Pro — One machine. Limitless potential.

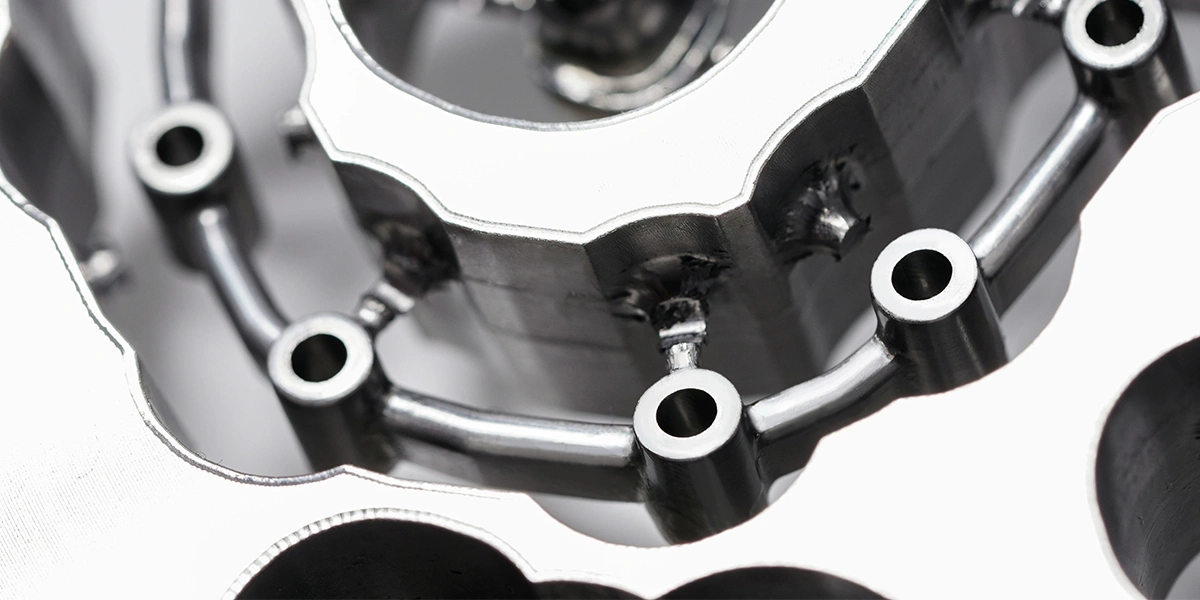

High Milling Accuracy

The W5 Pro is capable of performing precise thread milling and incorporates an automatic calibration function, reducing the error to less than 0.003mm.The success rate of getting teeth is over 97%

The best choice for milling CoCr

The 2.5kW large spindle equipped in the W5 Pro provides powerful power for CoCr milling. Meanwhile, the spindle torque of 398Ncm enables the equipment to easily complete the milling work of metal materials

Achieving a 30% Efficiency Enhancement

The zero-point quick change function has been upgraded. Changing the fixture only takes 1 to 2 seconds, which is fast and stable. The addition of the auto-calibration has shortened the calibration time from 40 minutes to less than ten minutes

Stable Working Performance

Durable and robust construction – Cast iron frame, nickel-plated anti-corrosion coating and cast iron milling chamber. The added Auto-Drainage Air Filter can reduce maintenance issues caused by neglected drainage

Perameters

Specifications

General

Processing Mode: Dry & Wet

Millable Materials: Crown, Bridge, Veneer, Inlay, Onlay, Abutment, Denture, Screw-retained bridge, Model cast, Occlusal splint, Surgical guide, Implant bar

Applications: Zirconia, Glass ceramics, Plastics, Wax, PEEK, Composite, Titanium, Pre-milled blanks

Power: 220V / 3.5kW

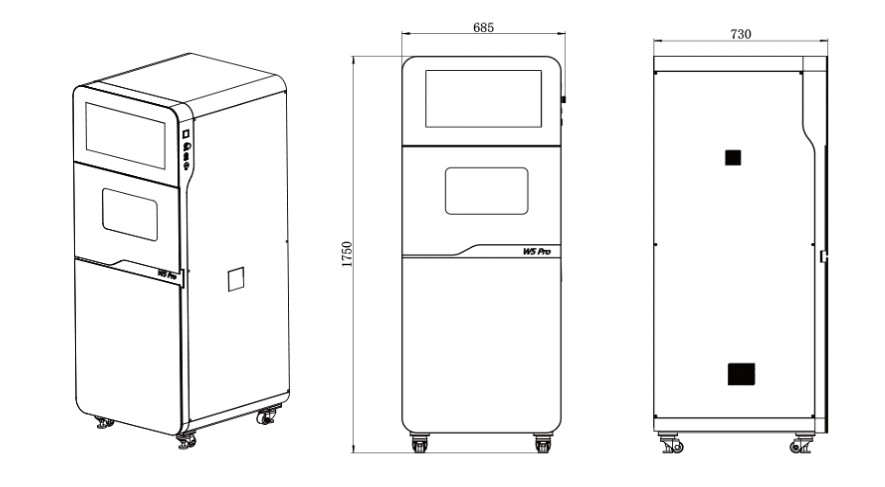

Dimensions: 685 × 730 × 1750 mm

Weight: 300 kg

Air Supply Pressure: > 0.5 MPa

Air Flow: > 100 L/min

Spindle

Speed: 60,000 rpm

Power: 2.5 kW

Collet: φ6 mm

Cooling Method: Water cooling

Structure Parameters

Basic Construction: Iron

Number of Axes: 5

Rotary Axis A: 360°

Rotary Axis B: +30° ~ -30°

X Axis Stroke: 220 mm

Y Axis Stroke: 145 mm

Z1 Axis Stroke: 130 mm

Tool Capacity: 24 × 2

Tool Setting Accuracy: 0.01 mm

Max Feed Speed: 4000 mm/min

Max Idle Speed: 8000 mm/min

Others

Certifications: CE (All models), FCC (North America)

Clamps: C-CLAMP, Pre-mill Abutment Holder, Block Holder

Request a Quote

If you are interested in acquiring this equipment, we would be delighted to assist you. Please feel free to fill out our contact form with your details and specific requirements, or give us a call at your convenience. Our team is ready to provide you with all the information you need and guide you through the purchasing process to ensure you make an informed decision.