DEPRAG W5 Max

5-Axis All-in-One Dental Milling Machine with Automatic Disc Changer

Precision & Efficiency Revolution in Dental Milling

Meet the W5 MAX: the most advanced all-in-one dental milling solution designed to handle everything your lab demands—from zirconia and titanium to glass ceramics and PMMA—with automation, power, and intelligence. Replace your calipers, wood blocks, and constant recalibrations. The era of AI-driven precision is here.

Key Highlights

Smart Automation

The W5 MAX is self-reliant. Thanks to elite calibration hardware and patented 3D automated software, it automatically calibrates itself, maintaining sub-5μm accuracy with no manual setup required.

Non-Stop Machining

Equipped with an 8-slot rotary automatic disc changer, the W5 MAX enables continuous production. Mill up to:

-

40 discs

-

48 pre-milled blanks

-

18 tools

-

8 blocks

This means less downtime, less manual intervention, and higher output.

Unrivaled Accuracy

-

Aerospace-grade HIWIN-C5 ball screws & P-grade guideways

-

HAOZHI 3kW water-cooled spindle (60,000 rpm)

-

INOVANCE high-resolution servo system with encoder

-

Harmonic reducer for high-precision rotary positioning

-

Finite element analysis (FEA) validated structure

High Efficiency

-

Automatic Tool Magazine for 18 tools

-

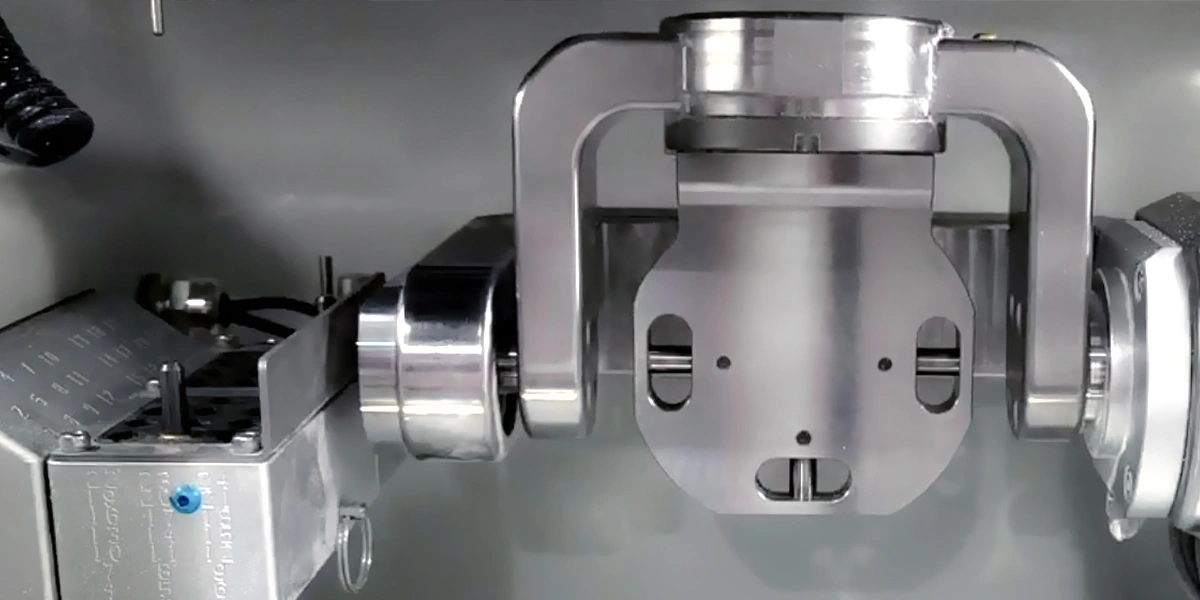

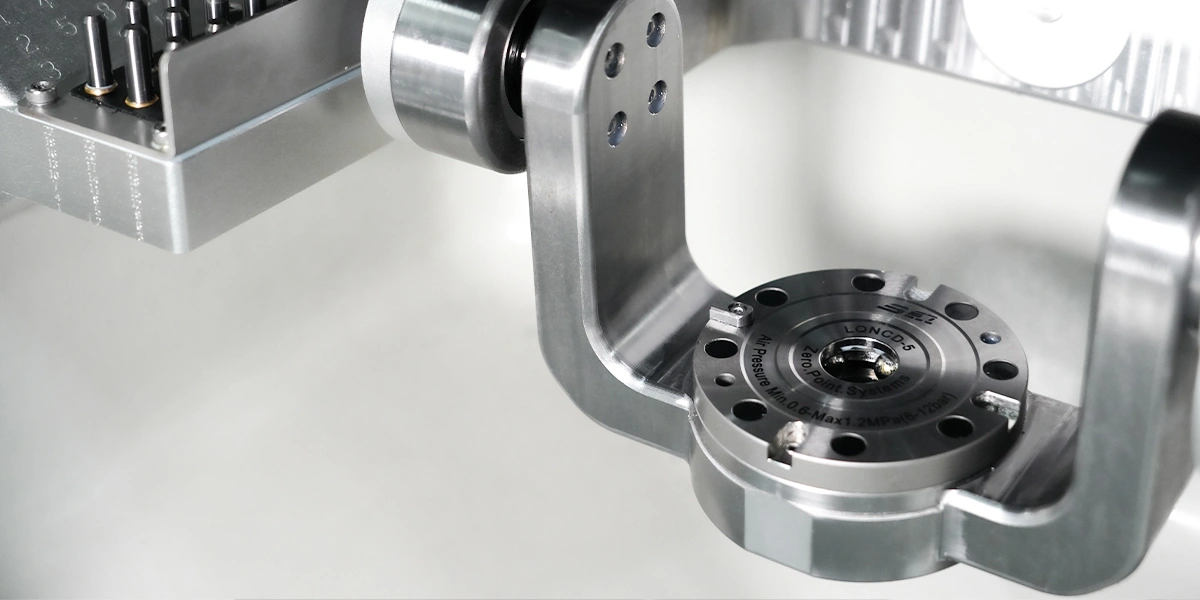

Zero-Point Quick-Change system

-

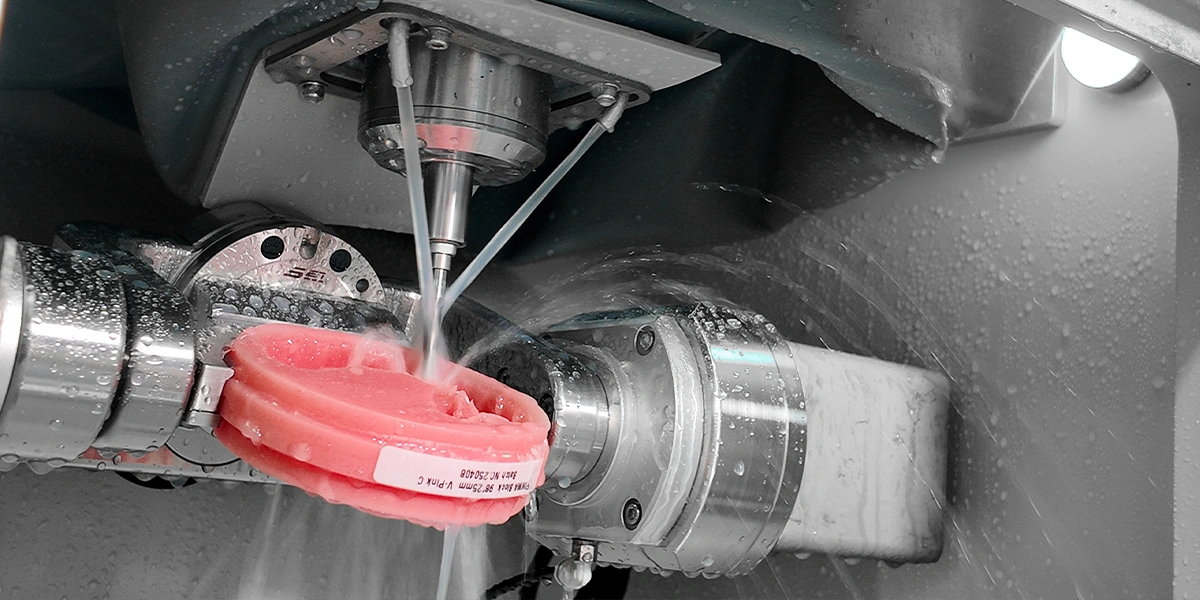

Dual-mode wet/dry switch

-

Supports discs up to 35mm thick

-

360° A-axis rotation and ±30° B-axis tilt for complex angulation

More Stable, More Durable

-

Heavy cast iron body

-

Floor-mounted structure for reduced vibration

-

Steel C-type B-axis

-

Components by HAOZHI, HIWIN, and INOVANCE

-

24-month warranty on core non-destructive parts

-

24-hour remote support

User-Friendly Design

-

Contaminant-free tool changer outside the working chamber

-

Drawable magazine for easy tool replacement

-

HD camera for remote monitoring

-

Real-time file sharing, NC memory recall, and bur life alerts

-

15″ touchscreen with Windows 10

-

Supports Millbox, Hyperdent, WorkNC

Product Manager’s Note

“Bring real change to your lab. With W5 MAX, you only need one machine to do it all.”

Applications

The W5 MAX is built for maximum material and indication versatility:

Machinable Materials

-

Zirconia

-

Titanium disc

-

CoCr

-

Glass ceramic

-

PMMA

-

PEEK

-

Composites

-

Wax

-

Pre-milled blanks

Dental Indications

-

Crown & Bridge

-

Veneer

-

Inlay / Onlay

-

Abutment

-

Denture

-

Screw-retained bridge

-

Implant bar

-

Telescopic crown

-

Protrusion splint

-

Occlusal splint

-

Surgical guide

-

Secondary crown

-

Model die, plate & cast

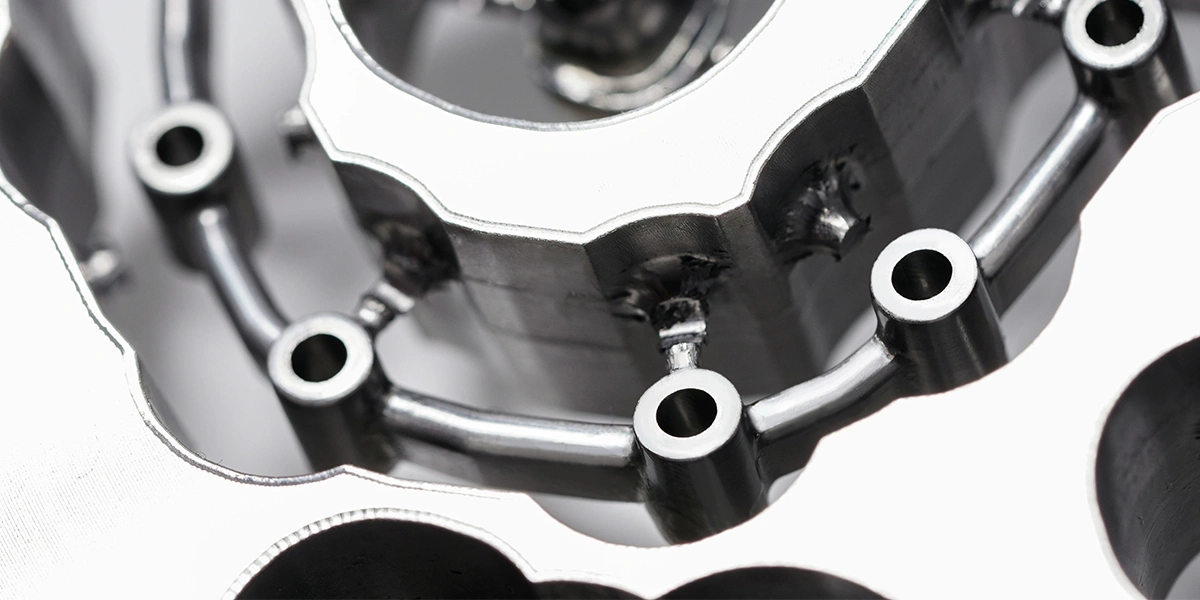

High Milling Accuracy

The W5 Pro is capable of performing precise thread milling and incorporates an automatic calibration function, reducing the error to less than 0.003mm.The success rate of getting teeth is over 97%

The best choice for milling CoCr

The 2.5kW large spindle equipped in the W5 Pro provides powerful power for CoCr milling. Meanwhile, the spindle torque of 398Ncm enables the equipment to easily complete the milling work of metal materials

Achieving a 30% Efficiency Enhancement

The zero-point quick change function has been upgraded. Changing the fixture only takes 1 to 2 seconds, which is fast and stable. The addition of the auto-calibration has shortened the calibration time from 40 minutes to less than ten minutes

Stable Working Performance

Durable and robust construction – Cast iron frame, nickel-plated anti-corrosion coating and cast iron milling chamber. The added Auto-Drainage Air Filter can reduce maintenance issues caused by neglected drainage

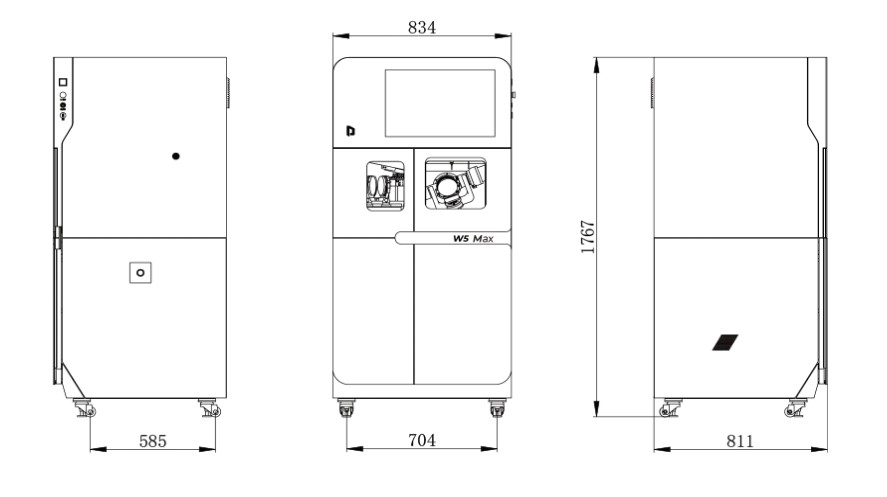

Perameters

Specifications

Request a Quote

If you are interested in acquiring this equipment, we would be delighted to assist you. Please feel free to fill out our contact form with your details and specific requirements, or give us a call at your convenience. Our team is ready to provide you with all the information you need and guide you through the purchasing process to ensure you make an informed decision.